📙 #070 - When to stop building tools and start using them

Sometimes things just need to change.

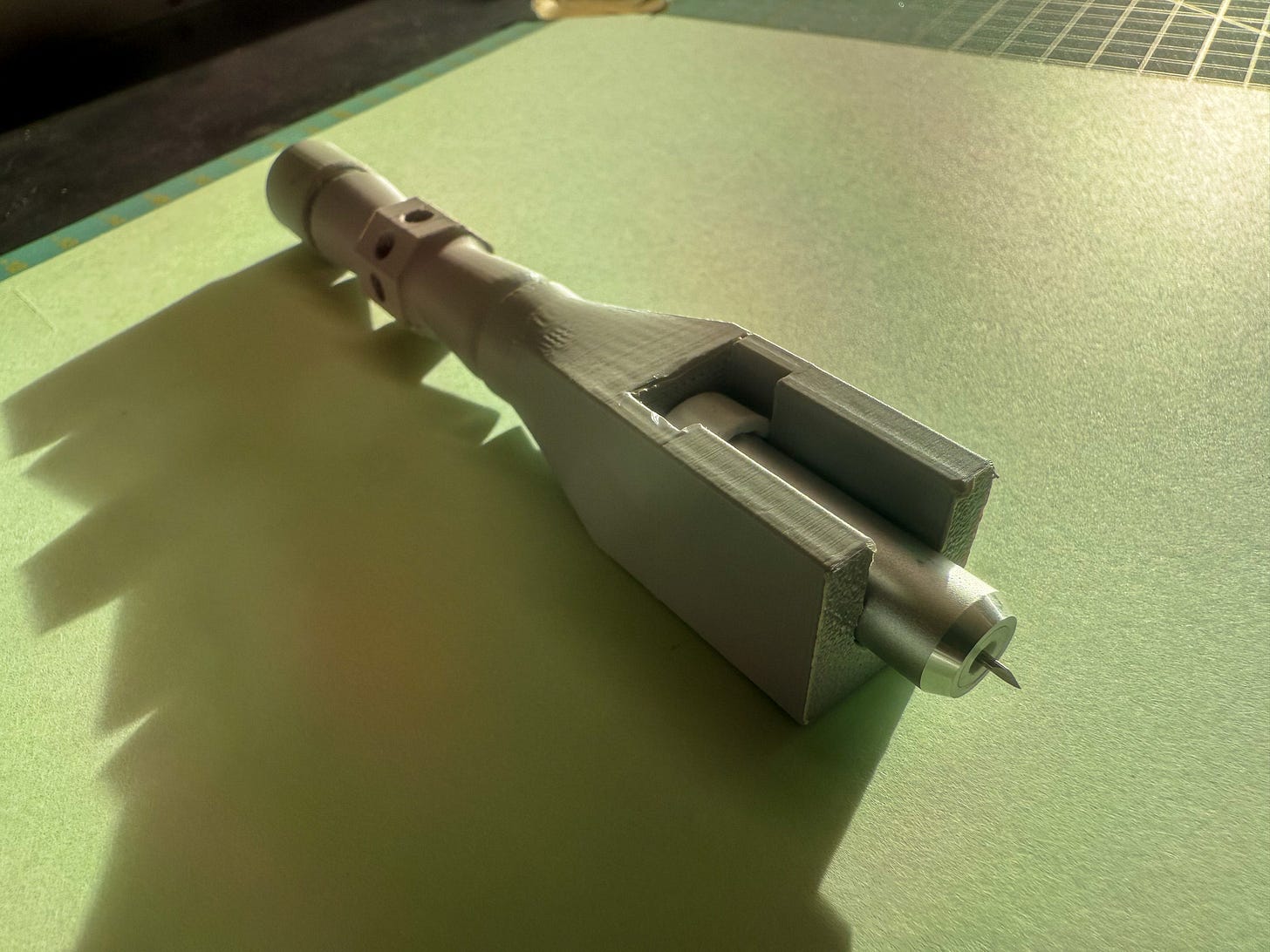

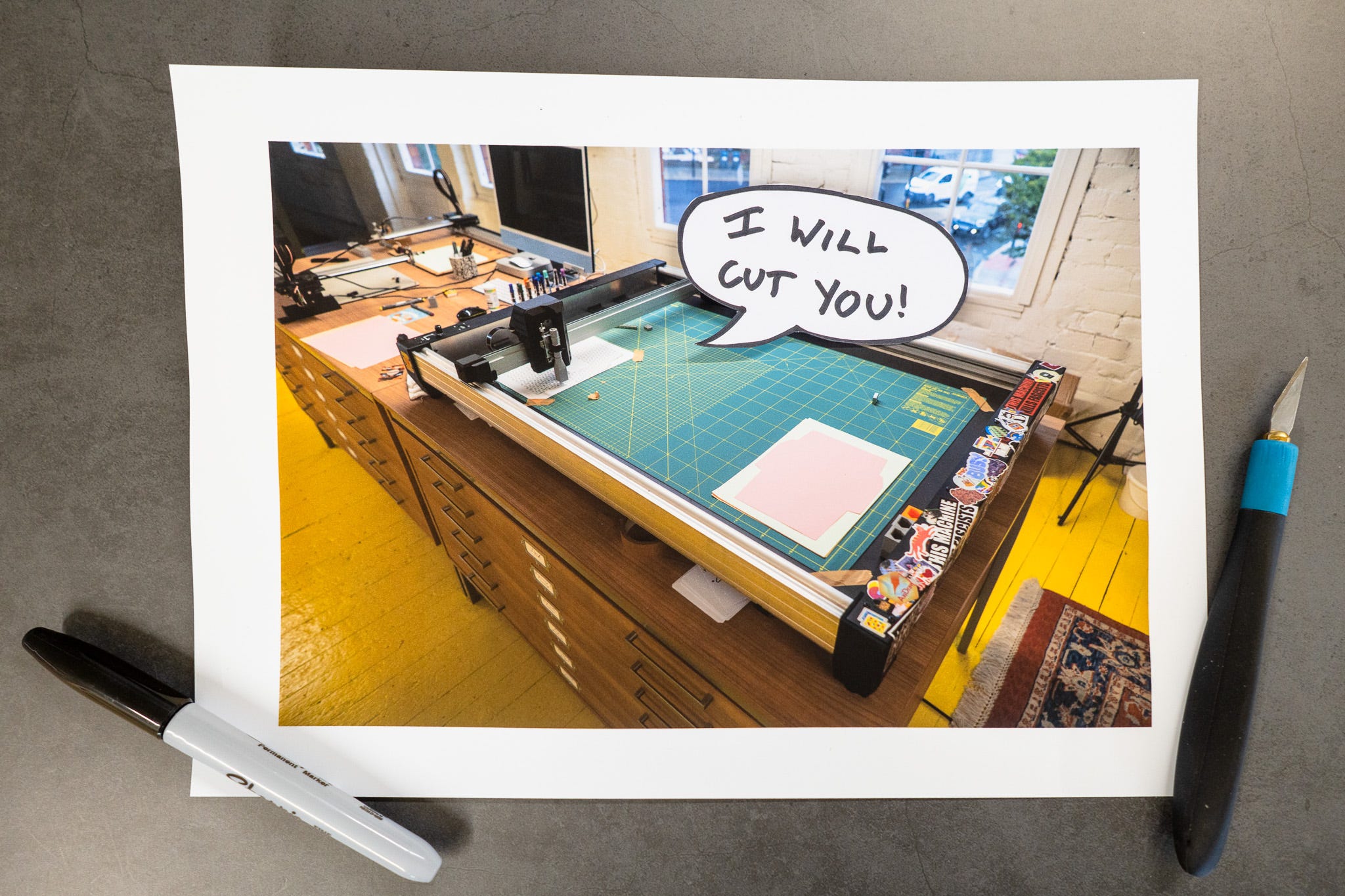

This was the state of my desk the other day, where I was very carefully and gently fitting a Cricut blade holder into a fractionally too small 3d printed Cricut blade holder holder, and it made me inordinately happy for reasons I’ll get into in a moment.

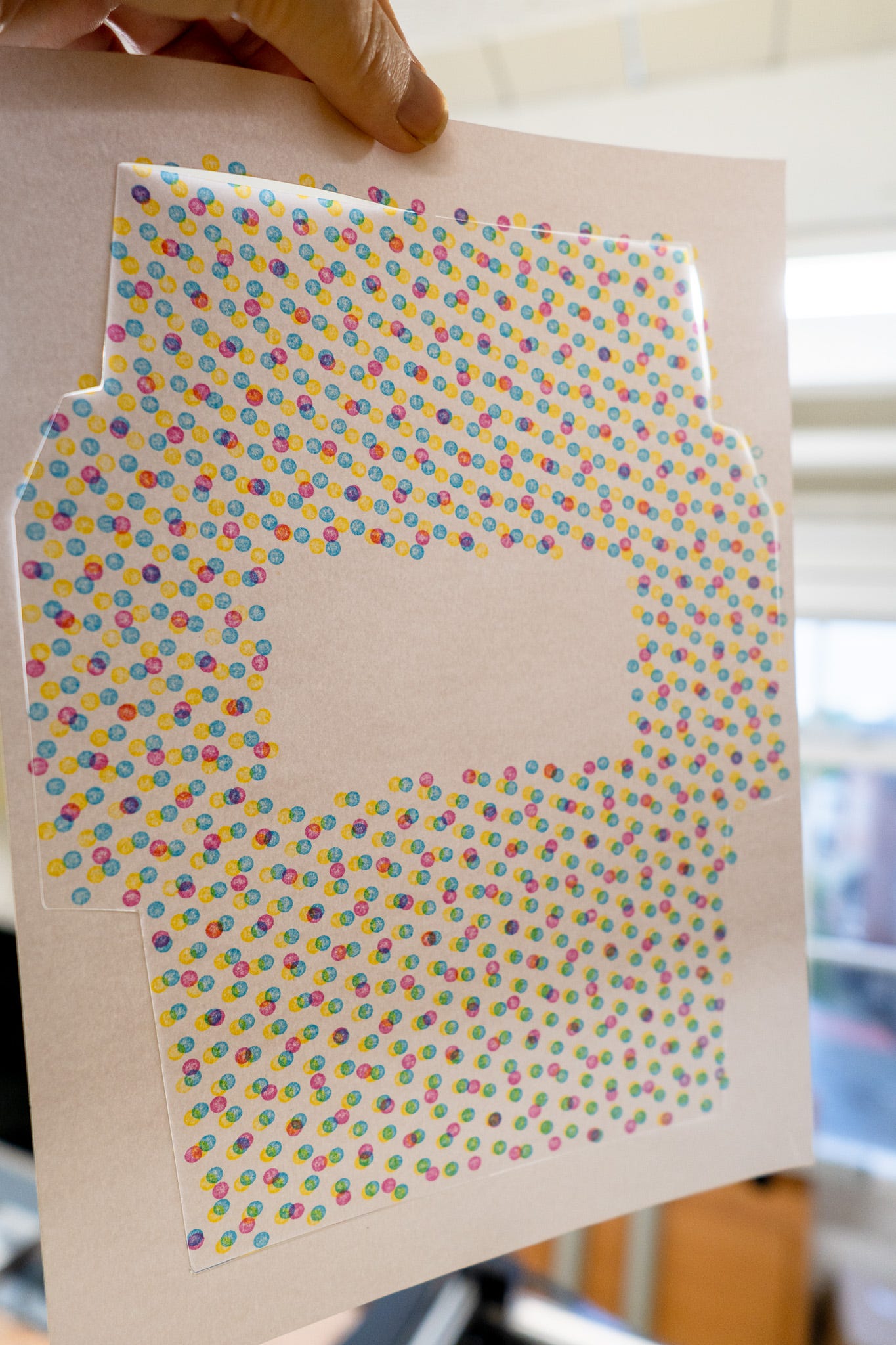

Here’s a terrible photo of the end result.

It’s never coming out of that holder, but I think I’m okay with that, the blade part is still swappable.

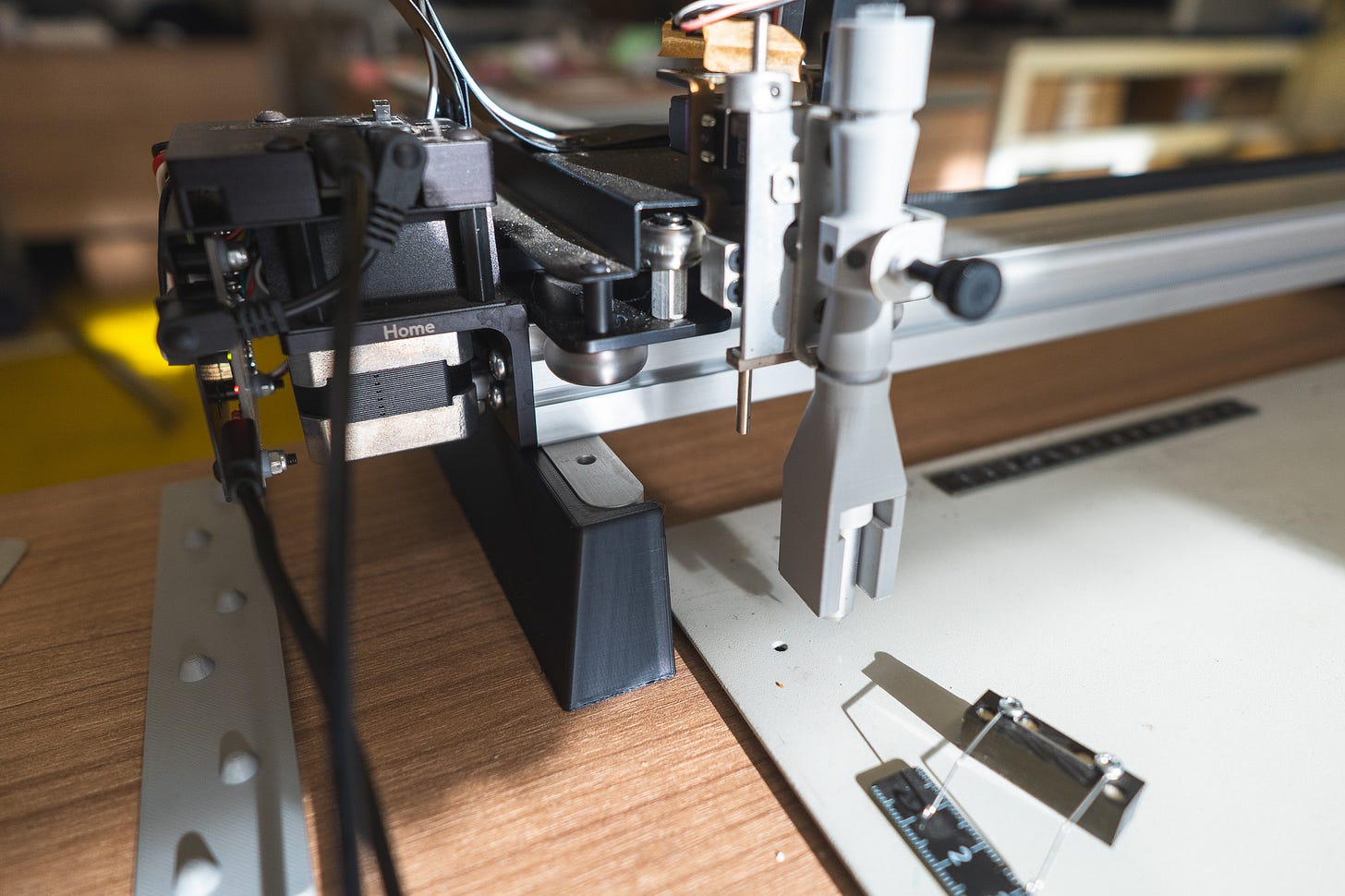

Last newsletter was all about envelope SVGs and tools to draw envelope outlines so they could be cut out, folded, stuck and glued and so on. So naturally my mind turned to getting the ArtFrame, (which has already been co-opted into holding rubber stamps), to hold a blade instead.

# PLOTTER STILTS

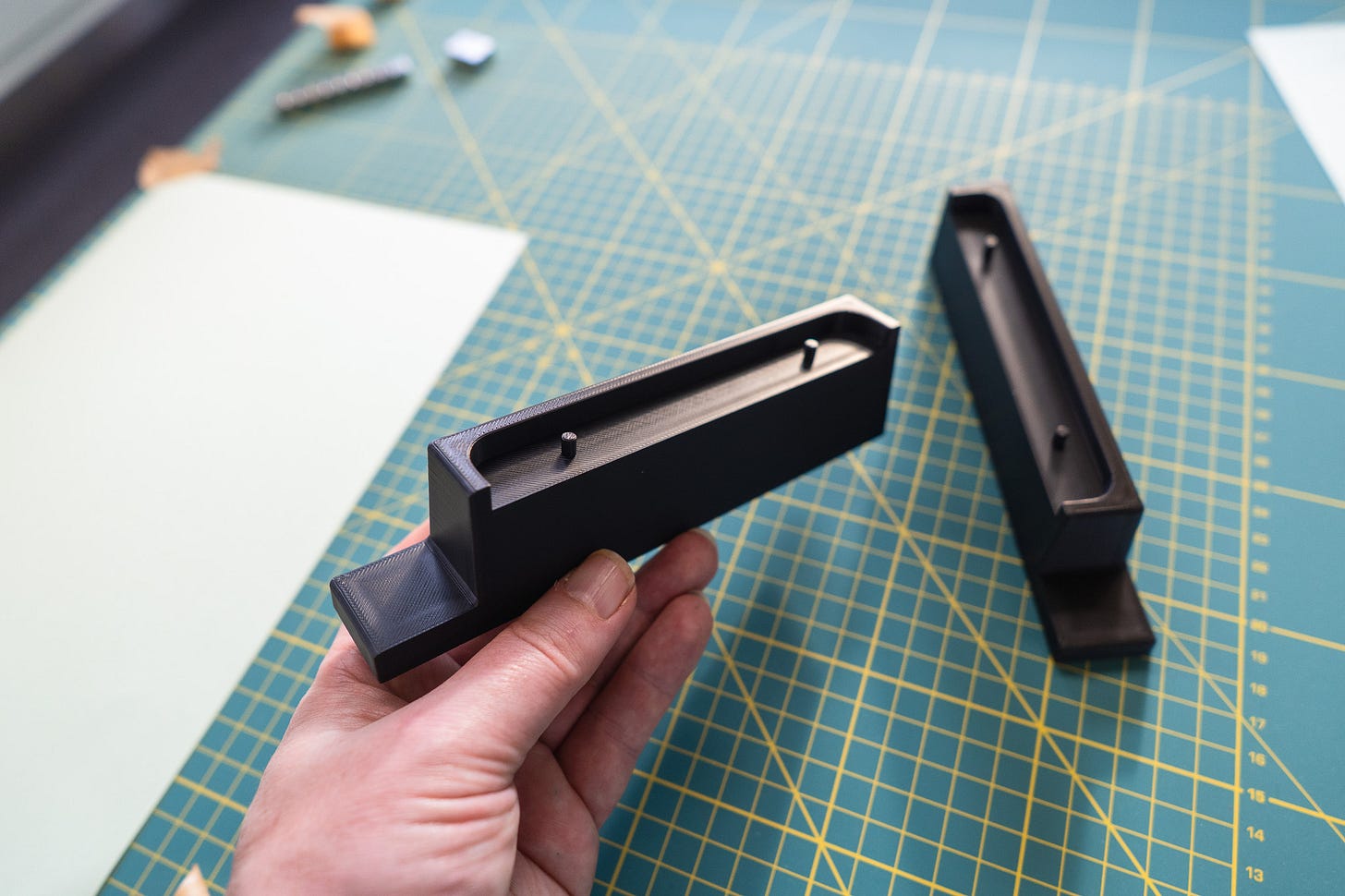

Surprisingly that worked on the ArtFrame (see later, kinda), but I also wanted to see if I could get a normal AxiDraw/NextDraw to hold the holder. That in turn had me making some “stilts” for the plotter, ‘cause the whole thing needed to be lifted up exactly 37mm…

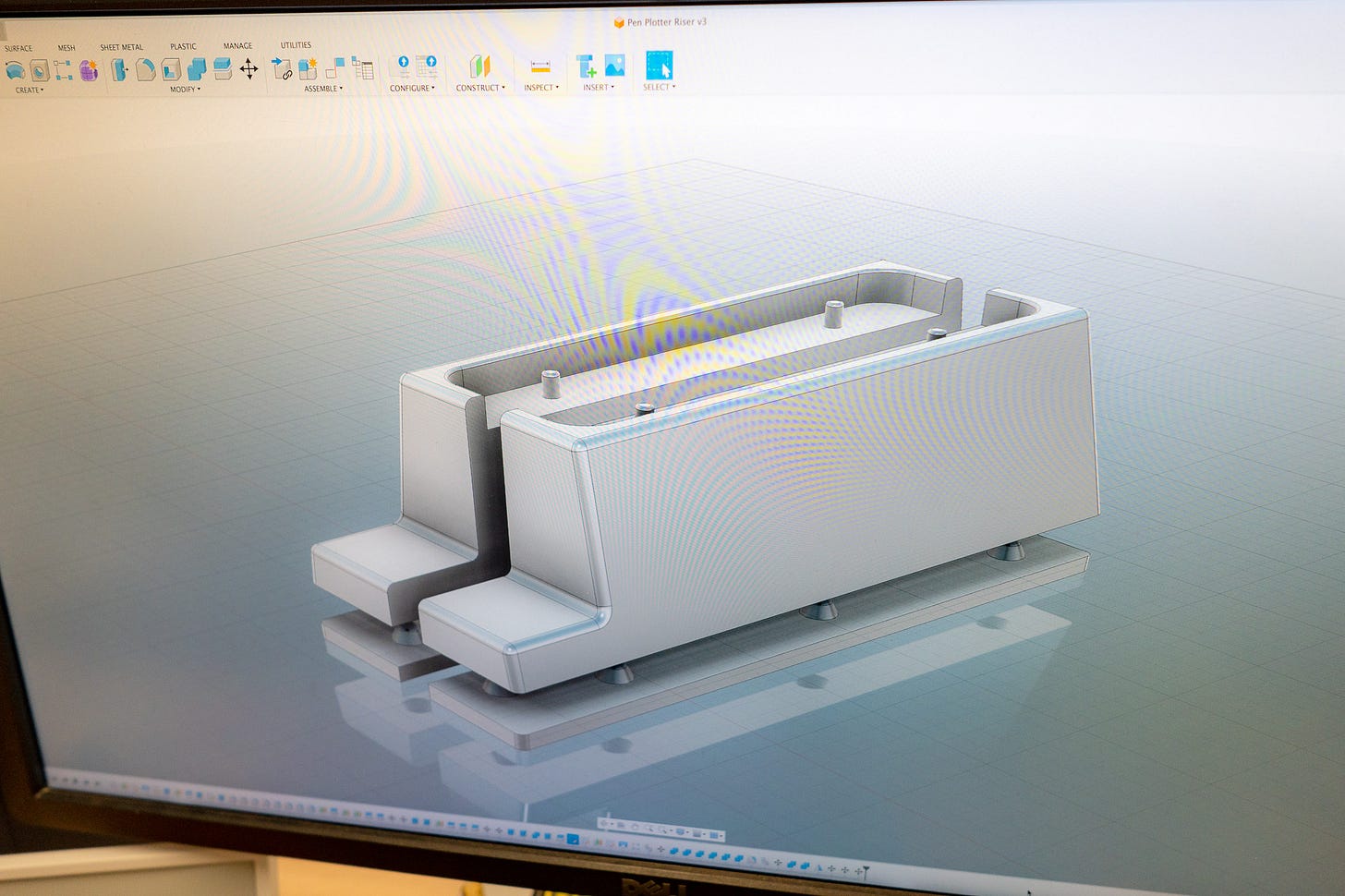

…the flat jutting out bit is so I can clamp them down to a table if needed. I also modelled and printed some “risers” which are 4mm high and “lock” into place with studs and holes, so I can stack as many as I need together (sticking rubber feet onto the lowest one).

If for some reason you feel like you need some 37mm high 3d printable Axi/NextDraw stilts in your life, then hit the button above, or use this link: https://revdancatt.com/files/plotter-stilts.zip

While I still don’t know if the cutter works well in a normal NextDraw, as I haven’t had a chance to try that yet, I do know that people often need to lift the whole machine up to hold things like brushes and the like, so perhaps this’ll help, although there is of course an easier way.

# CUTTING WITH THE ARTFRAME

The short answer is; yes you can! With some caveats and lessons learnt, here’s a kind of bullet list.

⚠️ The blade is more interested in dragging the paper (and cutting board) around than cutting through it.

⚠️ No matter how level your surface is, it’s not really completely level.

⚠️ Different papers have different thicknesses, obvs.

⚠️ You have to be very picky with tuning in the height (i.e. my gcode files won’t work for you).

Here’s the three things I learnt;

💡Taping the paper & board down definitely helped a lot, but didn’t totally solve the dragging paper problem.

💡I ended up creating a single gcode file that cut the outline 5 times, barely scratching the surface the first time, then getting 0.2mm deeper with each pass. Multiple passes means I was only ever making a very shallow cut on each pass, but would eventually get through thick paper. This almost stopped the paper dragging problem. I had to edit the gcode file by hand, copy & pasting the outline a few times and modifying the Z-height.

💡 Along the four long straight edges, top, left, right, bottom, I calculated where the middle was and made the blade lift up, skip a millimetre, then go back down and finish off the line.

This was so the envelope shape was never fully cut out of the paper, which made handling the sheets after cutting easier, and also stopped the blade dragging the paper around, with nothing more than the normal bit of tape in each corner.

I did this by editing the GCODE by hand (again), but a better solution would be to write code that automatically decides where to put the little “bridges” - you could probably even do perforations.

# WRONG TOOLS FOR THE JOB

The easiest way to raise up an AxiDraw (if you can’t find two books with identical thickness) is to cut a couple of blocks of wood and screw the AxiDraw to them. Maybe a two minute job at most, rather than fucking around in a CAD package for an hour and then 3d printing them.

But I don’t have a wood shop.

A better way to cut out envelopes and the like is with a die cutter, you know something designed for this type of thing. But I don’t have one of those either.

Another way would be to use the actual Cricut Maker I have sitting in a box. They solve the problem of paper dragging by having a sticky sheet to keep the paper in place and a spatula to remove it again. But I’ve always found it a pain in the ass to use, and the sticky sheet is either too sticky and you tear the paper removing it, or it’s not sticky enough.

Maybe a laser cutter would work 🤷♂️

Instead I have a 3d printer for “woodwork” type jobs, and an ArtFrame that draws, scores, cuts, stamps and letterpresses (kinda) for me, just at a much slower rate, because at this point it’s more of a universal tool than something that does one specific job. And I’m okay with that, especially as I can chain together uses; it can draw, them stamp, then cut all from the same file with pauses to change the tools.

Honestly, if I had a CNC lathe thingy, I think I could happily live at the bottom of the garden in a shed and the greenhouse for the rest of my days.

# TIME TO USE THE TOOLS

I divide my year up into quarters; the idea being that at the end of one and the start of the next I get to look back at what didn’t work, and then plan out the next quarter with this in mind. Being an artist often means self imposed deadlines are fuzzy and projects are never really done before they morph into the start of a new one.

Endless.

The quarterly review is a chance to break that cycle.

Mine is technically next week, but I already know what it’s going to be.

In the first quarter of the year I was; I can do work, the pen plotter tutorials, this & that, and weekly #weeknotes videos. But I just ended up doing work, this & that, and the #weeknotes, no tutorials.

In the second quarter I adjusted; work, pen plotter. tutorials, just this, no that, and #weeknotes.

Sigh.

In the third quarter, the one just gone, I was Okay!! Work, Tutorials & #Weeknotes.

But that just gave me the excuse to do this & that so I can record something for the #weeknotes video. Turns out shooting video of something makes that thing take about four times as long!

Want to sit down and make a notebook? Easy, fun… want to record some video about doing it; lights, camera, angles, editing? Suddenly it’s more than just that. Don’t get me wrong, I love making videos, but I have several thoughts about productivity of just doing & making vs doing, making & teaching, but that’s for another time.

Next quarter; Work & Tutorials!

I’ve spent a lot of timing making tools and systems to make my life easier, and, classic, each one has spawned the next, and the next.

I think I’m about to enter the season of just burrowing away and using the tools, code and systems I’ve spend all this time building, and not recording each and everything thing. There will always be a new tool or system to make, but I think I’ve got enough to keep me happy over the winter 😁

# THE DESK

I have a standing desk; it’s been locked off in the standing position and being used as my tutorial video shoot desk. I locked it off too keep continuity between shoots.

I now have enough of the first batch of tutorials filmed that I’ve decided I can move into editing mode, and moving forwards I’ll put the desk into position when I need it, and then return in back next to me the rest of the time.

I love my studio, it’s full of surfaces and draws, but aside from my worky-work computer desk, this moving standing/sitting desk is the only other one I can sit at to do-stuff and I haven’t been able to do that for about six months.

Frustrating.

It’s only been back in it’s new position for about three days, and I’ve already felt more creative than I have in a long time.

Joyful.

Who knew the answer was cutting shit up? Here I’m trying to figure out how to fashion a packaging box for a notebook out of a single A4 sheet, fun, tricky!

# THE END

The weekly #weeknotes videos are still going to happen, for what it’s worth, and more about that in this week’s video I guess.

Despite all the above about using the tools I’ve made, I am actually going to spend most of the next 12 weeks working on tutorials. The hours I have in the morning will now be spent editing footage, shooting b-roll and pick-up shots and getting all that done and dusted.

Things like making notebooks, folding envelopes and other bits and bobs are now relaxing in the greenhouse in the early morning/evening time. During “work hours” the machines will be doing their thing in the background, and then I get to carry the results home to fold, stitch, write and post.

Will this work? Who knows, I’ll find out in the next quarterly review. I guess the important part is to pick a point, and it may be an inconvenient one, where you force yourself to assess if things are working, is the current rabbit hole what you originally planned, and does it match the goals you set, or are you just flowing from one thing to the next (which is fine, but is that serving you?).

Anyway, these newsletters are still going to keep happening, the next one is due Thursday 2nd of October, but may be a little shorter (press X for doubt), and maths tells me there’ll be six of them in the next quarter, or maybe seven in a pinch, so we’ll have a few opportunities to look back at this newsletter and see how right or wrong I got it 😅

Love you all

Dan

❤️

If you're not already aware, the solution that you used for preventing the paper from moving after cutting out the envelope shape, leaving a small tab, is a common technique when cutting materials with a RNC router or mill. It's a good trick!

You mentioned a CNC lathe thingy so (at the risk of distracting you further!) I point you to the New Yorkshire Workshop, who manufactured his own 'EPIC woodcutting robot'. He has hours and hours of video of the build process, but has handily published a bitesize 40-minute edit of the build process. Subsequent videos of the machine in action are also impressive.

https://www.youtube.com/watch?v=wyR1ZyTX8Vw